Auto Parts Manufacturing Company

Introduction

As the automotive sector continues to evolve, the demand for precision, speed, and innovation in component production has never been greater. At the heart of this complex industry lies the auto parts manufacturing company, responsible for producing thousands of components that keep vehicles moving safely and efficiently. These companies are crucial players in the global supply chain, serving both original equipment manufacturers (OEMs) and the aftermarket.

This article takes a closer look at what defines a modern auto parts manufacturing company including its operations, technologies, quality standards, and the challenges it must overcome in an increasingly competitive world.

Role in the Automotive Industry

An auto parts manufacturing company is tasked with designing, engineering, producing, and delivering essential automotive components. These parts include everything from large engine blocks to tiny electronic connectors, each serving a specific function in a vehicle’s performance, safety, and aesthetics.

Without reliable parts manufacturing, the entire automotive ecosystem—comprising automakers, service centers, and end-users—would be disrupted. These companies act as a backbone that supports product innovation, cost efficiency, and global scalability.

Types of Auto Parts

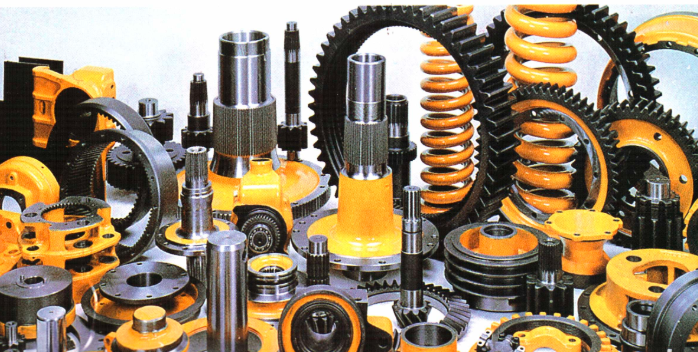

Manufacturing companies may specialize in one or more types of auto parts, depending on their expertise and infrastructure. Key categories include:

- Mechanical Parts: Engines, transmissions, gears, brakes.

- Electrical Components: Wiring harnesses, sensors, ECUs.

- Body and Interior Parts: Panels, dashboards, seats.

- Suspension and Steering: Springs, control arms, tie rods.

- Safety Systems: Airbags, seatbelt components, ABS modules.

Each type of component involves distinct processes, materials, and quality assurance systems.

Core Operations

Running an auto parts manufacturing company involves a wide range of operational areas:

1. Product Design

Design teams use Computer-Aided Design (CAD) and engineering simulations to create and test component concepts before production begins.

2. Material Selection

Depending on the part’s function, manufacturers choose materials such as high-grade steel, aluminum alloys, plastics, or rubber to achieve the right balance of weight, durability, and cost.

3. Production Processes

The company utilizes various production methods, including:

- CNC machining

- Metal stamping

- Plastic injection molding

- Forging and casting

- 3D printing for prototypes

4. Quality Control

Stringent quality control checks, often based on ISO and IATF 16949 standards, are implemented to ensure every product meets industry and customer specifications.

OEM and Aftermarket Services

Most auto parts manufacturers serve one of two markets:

OEM Manufacturing

These companies produce parts directly for automakers. OEM contracts are typically long-term, highly regulated, and require strict compliance with design and safety protocols.

Aftermarket Manufacturing

Aftermarket parts are made for vehicle repair, replacement, or customization. These can be original-equivalent parts or performance-enhancing modifications. Aftermarket production offers flexibility and access to a broader consumer base.

Technology in Manufacturing

To meet modern demands, a top-tier auto parts manufacturing company leverages advanced technologies throughout the production cycle.

Automation and Robotics

Automated systems and robotic arms are used to increase efficiency and reduce human error in assembly lines.

ERP and MES Software

Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) streamline operations, monitor performance, and ensure seamless coordination across departments.

Digital Twin Technology

Digital replicas of components allow engineers to simulate real-world performance, helping reduce development cycles and failures.

Data Analytics

Big data and artificial intelligence are increasingly being used to predict equipment maintenance, optimize supply chains, and enhance product design.

Quality Standards

Reputation and reliability are everything in this sector. A trusted auto parts manufacturing company adheres to global quality and environmental standards:

- ISO 9001 – General quality management systems.

- IATF 16949 – Automotive industry-specific quality standards.

- ISO 14001 – Environmental management.

- RoHS and REACH – Compliance for hazardous substances in parts.

Failure to meet these standards can result in rejected shipments, penalties, or contract loss.

See also: How to Implement Barcode Systems in Your Business: A Step-by-Step Guide

Workforce and Training

A skilled and adaptable workforce is essential. Employees range from mechanical engineers and CNC operators to quality assurance professionals and supply chain managers. The company often invests in:

- Continuous training

- Safety protocols

- Lean manufacturing education

- Cross-functional team development

The combination of experience, innovation, and employee engagement helps maintain competitiveness.

Challenges in the Industry

Running a successful manufacturing company comes with its own set of challenges:

1. Supply Chain Disruptions

Fluctuations in raw material prices and global crises can affect production schedules.

2. Cost Pressures

Automakers continuously push for lower prices, demanding innovation in cost-saving without compromising quality.

3. Environmental Regulations

New emissions and sustainability laws require process adjustments and cleaner materials.

4. Technological Upgrades

Falling behind on technology adoption can reduce efficiency and market relevance.

5. Counterfeit Parts

Especially in the aftermarket, counterfeit components can damage a company’s reputation.

Trends in Auto Parts Manufacturing

Several trends are shaping the future of auto parts manufacturing:

Shift Toward Electrification

EV components like battery housings and electric motors are now in high demand.

Lightweight Materials

Use of composites and magnesium alloys helps reduce vehicle weight and improve fuel efficiency.

Customization

3D printing and modular production systems allow for customized part design in smaller volumes.

Globalization

Companies are setting up operations in multiple countries to reduce shipping costs and meet local demand.

Sustainability

Eco-friendly practices like using recycled materials and renewable energy are becoming industry norms.

Choosing the Right Manufacturing Partner

For businesses seeking a reliable auto parts manufacturing company, here are some factors to evaluate:

- Production Capacity

- Technical Expertise

- Certifications and Standards

- Client Portfolio

- Response Time and Communication

- After-Sales Support

A good partner ensures timely delivery, product consistency, and transparent business practices.

Conclusion

The automotive sector cannot function without the contribution of an efficient and innovative auto parts manufacturing company. From engineering excellence to high-volume production, these companies ensure that automakers and consumers alike receive the quality and reliability they expect.

As the industry moves toward electric, autonomous, and connected vehicles, these manufacturing firms must continuously evolve to stay ahead. By investing in technology, quality, sustainability, and human capital, they position themselves as indispensable players in the global automotive value chain.