Geotextil y Geomembrana in Modern Engineering

In civil, environmental, and geotechnical engineering, the use of geotextil y geomembrana has become a standard approach for reinforcing soil, controlling water movement, and improving the longevity of infrastructure. These geosynthetic materials have revolutionized how we build and protect the environment in a cost-effective and sustainable way.

This article explores the distinct characteristics of geotextiles and geomembranes, their combined applications, and how they solve practical engineering problems.

Functions of Geotextiles:

- Separation: Prevent the mixing of different soil layers.

- Drainage: Channel water away from structures.

- Reinforcement: Provide structural support to weak soils.

These functions make geotextiles essential in roadbeds, retaining walls, and erosion control systems.

Key Uses:

- Containment: Lining landfills, ponds, and canals.

- Protection: Isolating hazardous chemicals.

- Environmental Barrier: Preventing seepage into groundwater.

Their durability, chemical resistance, and ability to remain watertight make them crucial in environmental containment systems.

See also: Tumblers Wholesale Bulk: The Smart Choice for Businesses and Brands

Why Use Them Together?

The combination of geotextil y geomembrana results in a system that offers both filtration and containment, along with added strength and protection.

Complementary Benefits:

- Geotextile as a cushion: Protects the geomembrane from punctures or abrasion by stones or soil.

- Improved filtration and drainage: While the geomembrane blocks water, the geotextile allows water movement without soil loss.

- Increased stability: Together, they improve the stability and life span of structures like embankments and reservoirs.

Using both materials optimizes performance in engineering projects and reduces long-term maintenance.

Construction Applications

1. Roads and Highways

Under road pavements, a layer of geotextile helps separate the subgrade from the aggregate base, preventing rutting. In areas where moisture control is critical, a geomembrane is used beneath or alongside the geotextile to stop water infiltration. This combined approach increases the durability of roads under heavy traffic and harsh weather.

2. Landfill Liners

One of the most common applications for geotextil y geomembrana is in landfills. Geomembranes act as a barrier to leachate, and geotextiles protect the liner while also filtering and draining liquid. This setup ensures environmental safety by preventing contaminants from reaching the groundwater.

3. Tunnels and Underground Structures

Tunnels face water ingress, which can damage concrete and steel over time. In these cases, geotextiles manage water flow and geomembranes offer waterproofing.

4. Irrigation Canals and Reservoirs

For agricultural projects, geomembranes stop water loss through seepage, while geotextiles support the liner and help manage the surrounding soil. This combination improves water conservation and reduces the cost of irrigation infrastructure.

Environmental Protection

In environmentally sensitive projects, geotextil y geomembrana are indispensable. Whether for hazardous waste containment or groundwater protection, these materials provide reliable solutions that meet international environmental standards.

- Oil spill containment ponds

- Mining tailings dams

- Stormwater management systems

These systems prevent harmful substances from entering ecosystems and help maintain the ecological balance.

Types and Variants

Geotextiles:

- Woven: Strong, grid-like fabrics used in high-load applications.

- Non-Woven: Felt-like materials ideal for filtration and drainage.

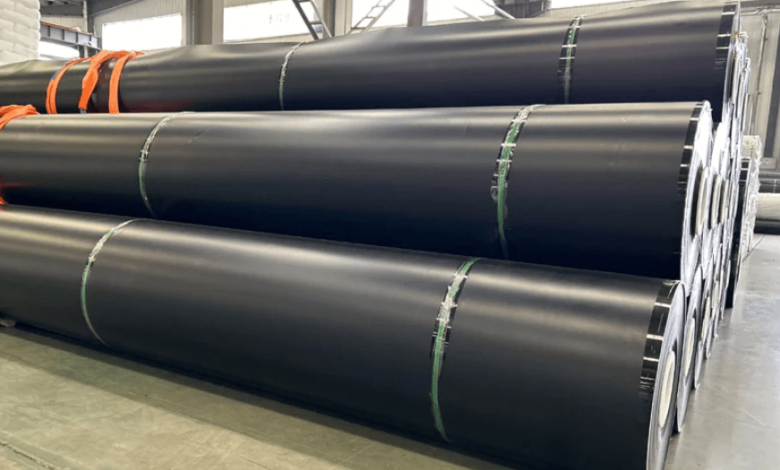

Geomembranas:

- LLDPE (Linear Low-Density Polyethylene): Offers flexibility and is ideal for irregular surfaces.

- PVC (Polyvinyl Chloride): Lightweight and easy to install.

Choosing the right type depends on the project’s mechanical, chemical, and environmental demands.

Installation Best Practices

To ensure maximum effectiveness, correct installation is essential.

Preparation:

- Level the surface and remove sharp objects that might puncture the materials.

Laying Geotextile:

- Unroll evenly without wrinkles.

- Overlap edges and anchor securely.

Placing Geomembrane:

- Position carefully on top of geotextile.

- Use heat welding or adhesives for joints.

- Avoid dragging to prevent damage.

Quality Checks:

- Inspect for tears or misalignments.

- Test seams using air pressure or vacuum methods.

Following these guidelines ensures longevity and structural integrity.

Common Challenges

Despite their effectiveness, several issues may arise with geotextil y geomembrana:

- Improper Seaming: Poor sealing leads to leakage. Using skilled labor for welding prevents failures.

- Chemical Incompatibility: Some geomembranes react with industrial chemicals. Material selection should be based on chemical compatibility tests.

Being aware of these potential pitfalls helps engineers prevent failure and protect project investments.

Case Study: Flood Protection in Latin America

In 2021, a flood mitigation project in Colombia used a dual-layer geotextil y geomembrana system to build emergency levees. The geomembrane created a water barrier, while the geotextile reinforced the base soil and protected the membrane. The result was a flood-resilient structure that withstood heavy rainfall and rapid water flow, protecting thousands of residents.

This example demonstrates how geosynthetics are not only efficient but also lifesaving.

Emerging Technologies

The field of geosynthetics continues to evolve with exciting innovations:

- Eco-Friendly Materials: Biodegradable geotextiles are being developed for temporary or low-impact projects.

- Hybrid Systems: Multi-layered products that combine geotextile, geomembrane, and drainage cores in a single unit are gaining popularity.

Conclusion

From road construction and water management to hazardous waste containment and erosion control, their combined application ensures structural strength, environmental protection, and cost savings.

As demand grows for sustainable and long-lasting construction methods, the importance of geosynthetic systems continues to rise.